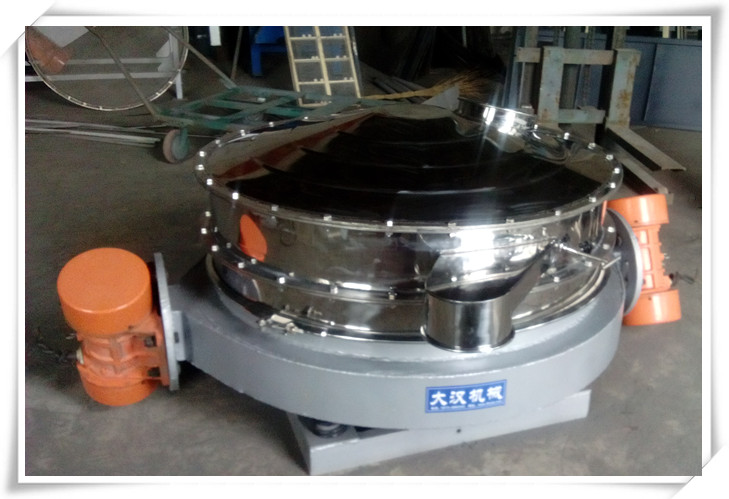

Manual Mixing:Direct Discharge Sifter is the Dahan company developed multi-functionhigh efficient screening equipment.The biggest feature is automatic discharge of impuritiesLarge production capacityand can be connected with screw conveyor easily.

►Introduce

Direct discharge sifter is a new and multifunctional screening machine, which can be installed one or two vibration motors according to customer’s specific situation.Vibration source is divided into single motor and double motor structure.Material trajectories have many adjustment form,equipment applicability increased significantly,material direct emissions have greater capacity.More used in flour,starch,washing powder,metal powder,additives,chemical industry,the mining industry such as particles of powder rough screening or precision sieving.Large quantity,easy to combine with production line,and can choose between 600 mm to 1800 mm.

►Working Principle

Direct discharge sifter can be installed one or two vibration motors according to customer’s specific situation. Single vibrating motor can make the material produces vibration up and down,and not have automatic discharge function.Double vibrating motors can produce eddy motion on the screen,with functions of automatic discharge.

►Features

(1)Beautiful appearance,durability.

(2)Small volume,does not occupy a space,easy to move.

(3)Low energy consumption,high efficiency.

(4)Disassembly easy,inside and outside easy to clean,meet the food and pharmaceutical industry specifications.

(5)Automatic operation, can 24 hours of continuous production.

(6)low noise design.

(7)Seal is rigorous,the liquid does not leak,dust does not float in the sky.

(8)Monolayer or multilayer use,multistage filtering.

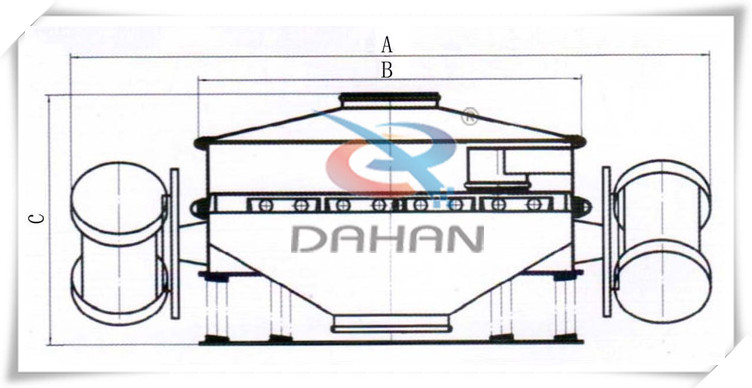

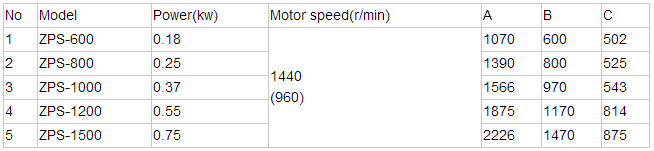

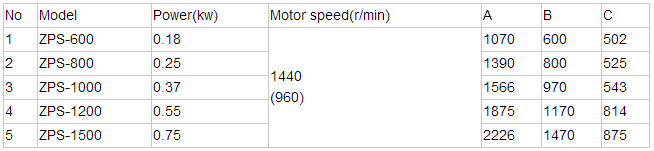

►Technical parameters

►Applications

Direct discharge sifter is used in screening granules and powders, which is suitable for single-deck sieving and screening on raw materials of small production of fewer impurities, such as flour, starch, detergent, metal powder, additive, chemicals, non-mining industries etc.

►Technical parameters

►Applications

Direct discharge sifter is used in screening granules and powders, which is suitable for single-deck sieving and screening on raw materials of small production of fewer impurities, such as flour, starch, detergent, metal powder, additive, chemicals, non-mining industries etc.