Manual Mixing:

Horizontal airflow screen sifter machine is a kind of screening machine making use of centrifugal force and cyclone for material separation.It is especially suitable for grinding plant powder,Such as:Chinese herbal medicine powder;Spices:curry powder,ginger powder,garlic powder,chili powder,pepper powder material etc.Cosmetics,nano tio2,mica powder,pearl pigment superfine powder and so on.

► Introduction

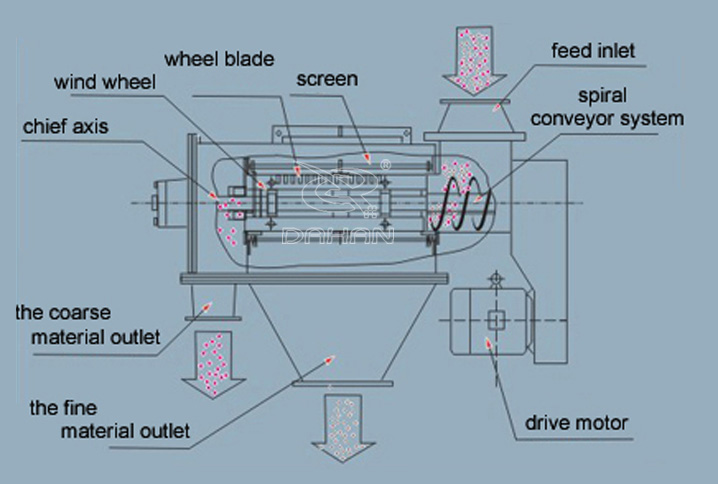

The Horizontal airflow screen sifter machine is a kind of screening machine making use of centrifugal force and cyclone for material separation.It is available with a cylindrical sieving chamber in which there are helical paddles supporting rotation motion.Screw conveyor is employed for material feeding. While propelling the feeding material against the screen,the rotating paddles also create centrifugal force and cyclone which accelerates the particles through the apertures.The centrifugal screen is designed with two outlets. Fine materials that can pass through the screen mesh are discharged via the fine material outlet,while others that can not pass through the screen are discharged from the coarse material outlet along the wall of the screen cylinder.

The Horizontal airflow screen sifter machine is a kind of screening machine making use of centrifugal force and cyclone for material separation.It is available with a cylindrical sieving chamber in which there are helical paddles supporting rotation motion.Screw conveyor is employed for material feeding. While propelling the feeding material against the screen,the rotating paddles also create centrifugal force and cyclone which accelerates the particles through the apertures.The centrifugal screen is designed with two outlets. Fine materials that can pass through the screen mesh are discharged via the fine material outlet,while others that can not pass through the screen are discharged from the coarse material outlet along the wall of the screen cylinder.

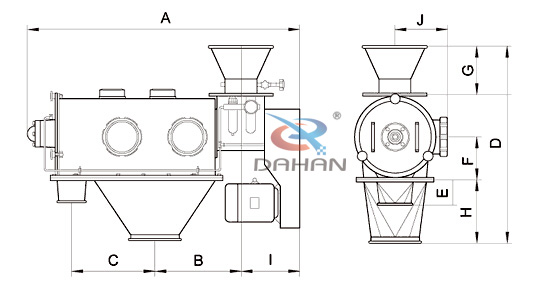

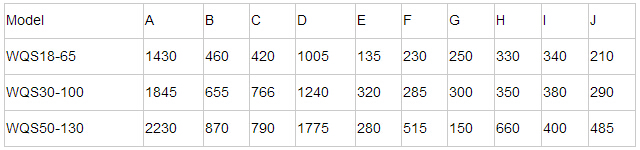

►The rough drawing of airflow screen sifter machine

►Features

1.The whole machine is in a small size and light so that it is stable in operation, free from vibration and noise, and with its good sealed structure, it is free from dust and performs in high efficiency.

2.The shell of machine is in a new design which makes it easy to install and convenient to control.

3.The machine can operate either in a single unit or multiple units, and it is safe and reliable for a long time operation.

4.The screen-mesh can be cleaned automatically by cyclone.

5.The machine has the function of re-crashing the agglomeration materials.

6.The new type roller bearing can prolong the service life.

7.The machine can work with the pneumatic conveying systems, and materials can be directly sent into the wind path to save resources.

8.New design:The airflow protection system can transfer the purified air to the two ends of the device,which will reduce the temperature created in the operation of the device