Manual Mixing:

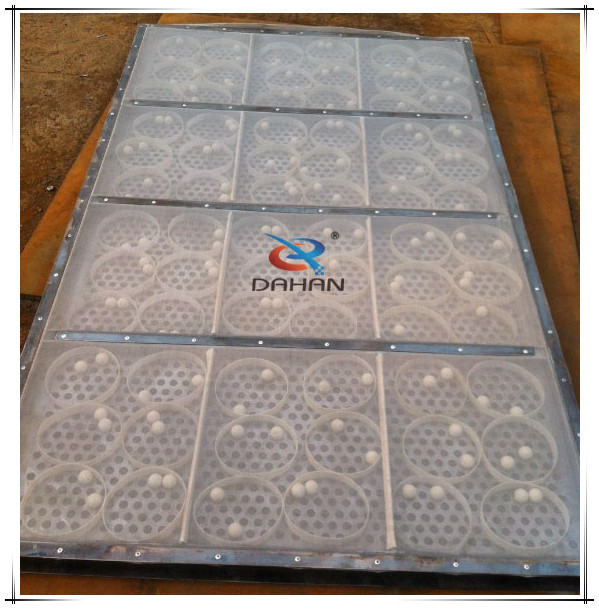

DZSF-1030 linear vibrator screen have one layers screen mesh and two discharge holes,which made of carton steel,two vibrating motor of 0.75KW.It has less energy consumption,high output and longer service life.

►Introduce

Linear vibrator screen is an efficient new screening equipment, which widely used in mining, coal, metallurgy, building materials industry, two sets of horizontal vibration motor to be power source,two synchronous motors are reversely placed so that the exciter generate reverse excitation force, the exciting force generated by eccentric block cancel each other out on the parallel direction of motor axis,and stack together with the perpendicular direction of motor axis, so its trajectory is linear.Linear vibrator screen is suitable for particle size from less than 10mm.

►Feathers

1. Good sealing, without dust pollution;

►Feathers

1. Good sealing, without dust pollution;

2. Easy to change screen mesh, long service life;

3. High screening efficiency,

4. Simple structure;

5. Discharge material automatically, fit the production line;

6. The sieve box is welded by steel plate and sectional material;

7. It has good whole rigidity and runs steady.

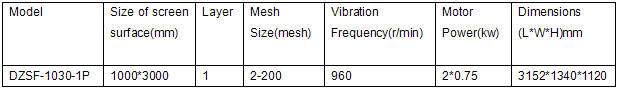

►Main technical parameters and Rough diagram

►How to choose suitable model for you?

1.How much is the hourly output?

2.What's the name of raw material will be screened?

3.How many layers do you need?

4.What's the sieve mesh size of every layer?

5.What is the material of machine?(carbon steel,stainless steel or others)

►Installation and adjustment

Linear vibrator screen should be fixed on dedicated foundation through embedded bolts. If there is no special foundation,it should lay anti-vibration rubber plate between the working table and the equipment basement.Before using,You must be configured prior to use safe and reliable protective grounding wire.

►Installation and adjustment

Linear vibrator screen should be fixed on dedicated foundation through embedded bolts. If there is no special foundation,it should lay anti-vibration rubber plate between the working table and the equipment basement.Before using,You must be configured prior to use safe and reliable protective grounding wire.

Note:After installation is complete,before starting,must remove device that it is used for fixed screen body and machine basement.

After the installation of new linear vibrating sieve is completed, you shall check the following requirements:

1.Check vibration motor winding insulation resistance to ground,if <20MΩ must be dried before using.

2.Spring should be completely vertical embedded spring retainer to ensure that the balance of the screen body.Vibration part can not have any contact with other object of outside the machine.

3.Close the power switch,make sure the vibration motor synchronous reverse rotation,holding 10-20 minutes idling.If there is abnormal sound when the equipment is running,it should be promptly shut down for inspection.