Manual Mixing:

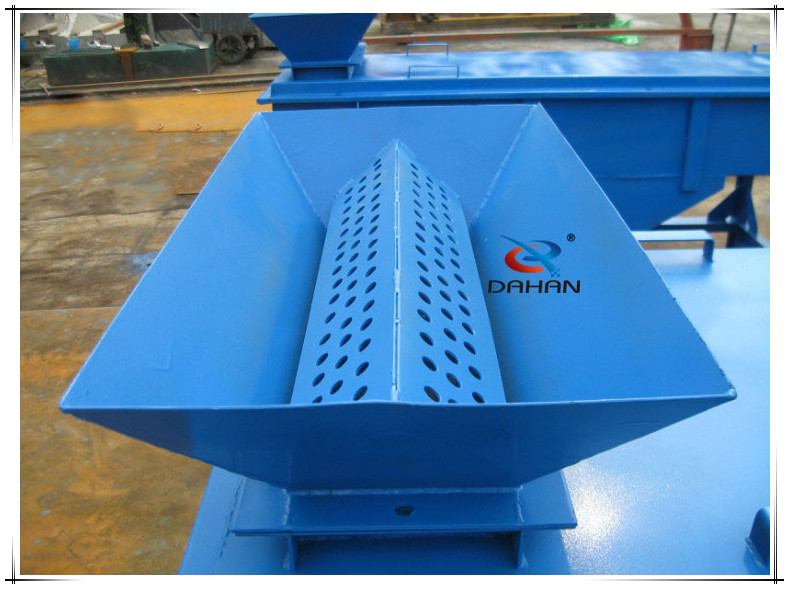

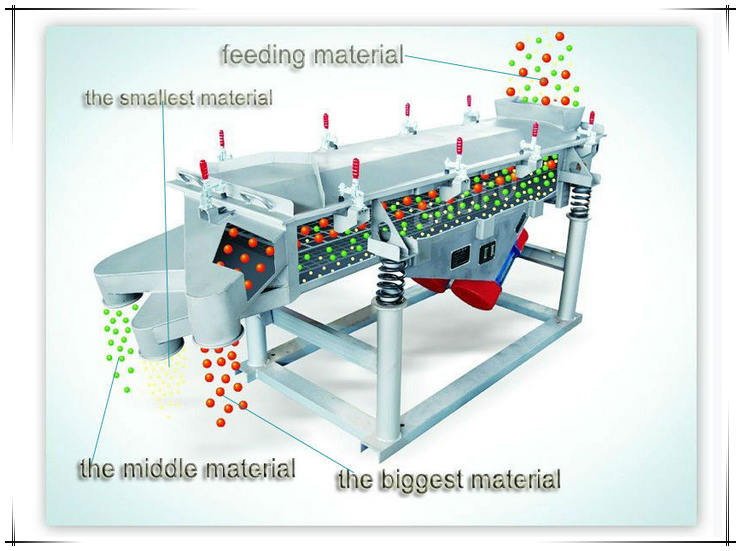

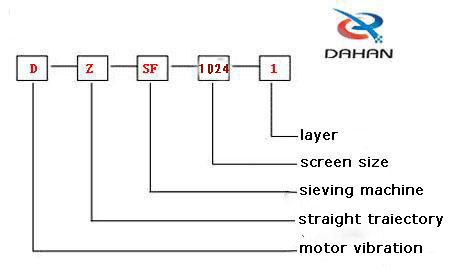

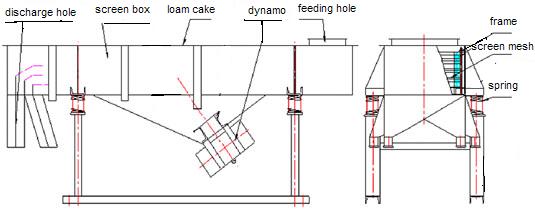

Linear classifier vibrating sieve is made of carbon steell and consist of screen box,screen mesh frame,screen mesh,two sets vibrating motor or vibrating exciter,motor base,damping spring,support frame etc.Square vibrating separator screen can be widely used in metallurgy,mining,coal,power,building material,fire-resistant material industries etc.

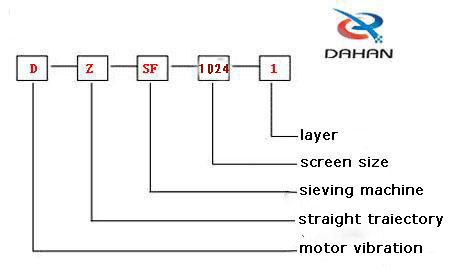

Linear classifier vibrating sieve is an efficient new screening equipment from professional vibrating sieve manufacturers, which widely used in mining, coal, metallurgy, building materials industry, two sets of horizontal vibration motor to be power source,two synchronous motors are reversely placed so that the exciter generate reverse excitation force, the exciting force generated by eccentric block cancel each other out on the parallel direction of motor axis,and stack together with the perpendicular direction of motor axis, so its trajectory is linear.Linear vibrating screen is suitable for particle size from less than 10mm.

►Feathers

1. Good sealing,without dust pollution;

2. Easy to change screen mesh,long service life;

3. High screening efficiency;

4. Simple structure;

5. Discharge material automatically, fit the production line;

6. The sieve box is welded by steel plate and sectional material;

7. It has good whole rigidity and runs steady.

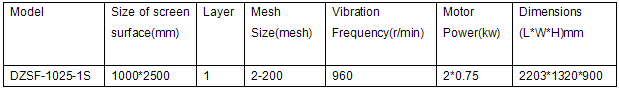

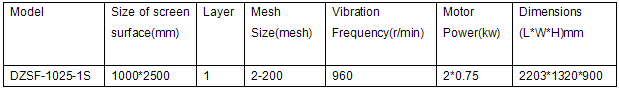

►Main technical parameters and overall dimensions

►Main technical parameters and overall dimensions

►Maintenance

Linear classifier vibrating sieve is one of the most commonly used vibration screen. Its maintenance and repair is essential, as good maintenance strategy and maintenance method can effectively prolong the lifespan of linear vibrating screen. So, let us take a look at the maintenance strategies and maintenance methods of linear vibrating screen.

The maintenance strategies of linear vibrating screen can be divided into three phases, before use, in use and after use.

Maintenance before use: linear vibrating screen should equip with electrical protection device; for initially use, anchor bolts should be checked each time before using in order to prevent loosening; check for damage on the screen mesh etc..

Maintenance in use: check the rotation of motor, if does not meet the requirement, adjust the power phase sequence; check unusual of the vibration; examine the stability of current.

Maintenance after use: periodically check the lubricate situation of machinery components, every two weeks operation, need to add the lubricating oil; after a total operation of one thousand five hundreds hours, check the wear of bearing; if long time do not use it, insulation resistance should be measured before use.