Manual Mixing:

Ultrasonic vibrating screen is 220 v50 hz power into high frequency electric energy of 38 KHZinput ultrasonic transducerturning it into 38 KHZ mechanical vibrationso as to achieve efficient screening and purpose of the cleaning networkmakes the ultra micro powder screening for easy.The processed materials do three dimensional vibration at the same time add Ultrasonic vibration of high frequency and small amplitude.

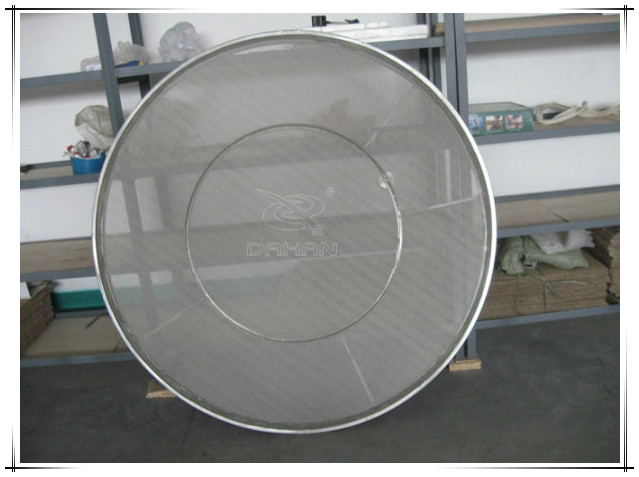

►Introduction

Ultrasonic vibrating screen makes processed material do traditional three dimensional vibrations, and at the same time it adds another vibration (mechanical waves) of low-amplitude and high-vibration frequency to achieve good screening result for sieving super-fine processed materials.

Ultrasonic vibrating screen screening system is a kind of simple and practical,reliable screening system,it is currently the most effective solution of mesh plug and domestic screen of a major technological breakthrough.

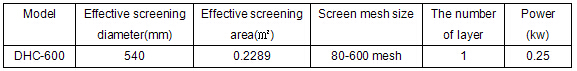

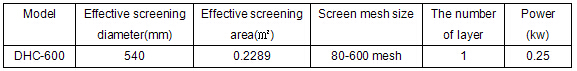

►Ultrasonic technology parameters

The biggest ultrasonic power output:200W

Output rated voltage:900V

Maximum Output Current:1A(limiting current)

Fuse:100-120V: 2*2.5A slo blo 200-240V: 2*1.25A slo blo

Protection class:IP65

Pollution degree:2

Environment temperature:-10-35°C

►Ultrasonic vibrating screen feature

►Ultrasonic vibrating screen feature

By improving the low density of powder in the gravity settling down and sliding,improve the high density of metal in the front-end ports stranded or wedging and the adhesion effect of electrostatic powder,to improve the quality of screening efficiency and screening.In screening pass rate,usually more than the ordinary vibration sieve pass rate of 50% to 440%.

(1)To reduce or not produce clear screen time.

(2)Do not produce powder pollution.

(3)Keep the mesh size,stable screening accuracy.

(4)Decomposition of adhesive material,reduce on the screen.

(5)Reducing frequency of screening.

►Applicable material

Alloy powder, aluminum powder, stainless steel powder, tungsten power, nickel powder, cobalt powder, coating powder, quartz powder, magnetic powder, silicon powder, malt powder, coffee powder, resin powder, mica powder.