Manual Mixing:

Valve circle vibro sifter is mounted with 0.25kw vertical vibrating motor.There are the diameter of 600mm,one layer screen mesh with three dischange holes.Mainly used in screening material of high output,made of stainless steel.Accept customized service.

Circle vibro sifter is a kind of high precision fine powder screening machine, works by the upright motor as vibration source, installed on both ends of the motor on the eccentric hammer, the motor rotation movement into horizontal vertical slope of three dimensional movement, then pass the movement to the screen surface at the ends of the regulation on the phase Angle, can change the course of movement on the surface of the material in the screen, vibration due to its operation principle, many enterprises are also called the three dimensional vibrating sieve filter, according to shape structure is part of the customers' call for circular sieve, from the material point of standard sieve and normal vibrating sieve, and material contact part with 304 stainless steel material, basement with carbon steel material.

►Production details

►Features

1. High efficiency, refined design, duration,any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenience washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration of screen, only 3-5 to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 lagers are suggested.

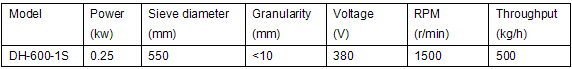

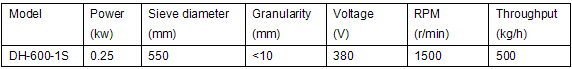

►Parameters

►Use and maintenance

►Parameters

►Use and maintenance

1, the machine shall be equipped with electrical protection device.

2, the machine is running early, check every day at least once a bolt to prevent loosening.

3, when the motor direction of rotation does not meet the requirements, you can adjust the power supply phase sequence.

4, the motor should guarantee good lubrication, each running about two weeks to add lithium grease (ZL-3) once, come on, through the oil by adding appropriate amount of lithium grease cup.

5, the machine running total of 1500 hours, check the bearings, if serious injury should be immediately replaced.

6, the machine parked or garaged when used again after a long time, measure the insulatio n resistance should be used to measure 500-volt megger.