Manual Mixing:

SUS Sulfur powder vibrating sieve is mounted with 1.5kw vertical vibrating motor.There are the diameter of 1500mm,one layer screen mesh with two dischange holes.Mainly used in screening material with high output.Accept customized service.

Sulfur powder vibrating sieve is a kind of high precision fine powder screening machine, works by the upright motor as vibration source, installed on both ends of the motor on the eccentric hammer, the motor rotation movement into horizontal vertical slope of three dimensional movement, then pass the movement to the screen surface at the ends of the regulation on the phase Angle, can change the course of movement on the surface of the material in the screen.

►Features

1. High efficiency, refined design, duration,any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenience washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration of screen, only 3-5 to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 lagers are suggested.

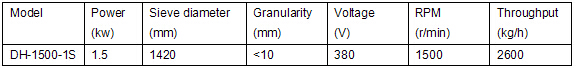

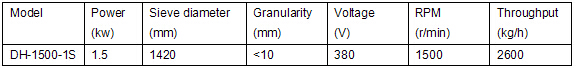

►Technical Parameters

This machine is very simple and quick method for change screen,just follow the order shown below,no more than five minutes,can be done for replace screen.

►Technical Parameters

►Advantage and method of replace mother-son screen mesh

1.Save time(3-5 minutes to complete screen replacement).

2.Save manpower, for replace screen just two people.

3.Increase fluency production line.

4.Increases screen life, bouncing ball does not directly strike a fine mesh.

5.Increase the screen using the area.

This machine is very simple and quick method for change screen,just follow the order shown below,no more than five minutes,can be done for replace screen.

Pls provide the following information for us:

1. material name, the density(kg/m3), water content(%).

2. the necessary capacity you required(per hour)

3. Machine material. Pls choose one:

a. All stainless steel 304

b. All carbon steel

c. The contacting part is stainless steel,the other parts is carbon steel or spraying plastic.

d.Contact part with plastic.

4. the dimension of the machine can be designed for you.

5. Additional parts ,like the mobil wheel, removing-dust hole and noise-proof base,can be easily fixed and maintained.

6. How many layers you need??

7. Pls inform the voltage&frequency in your city.