Manual Mixing:

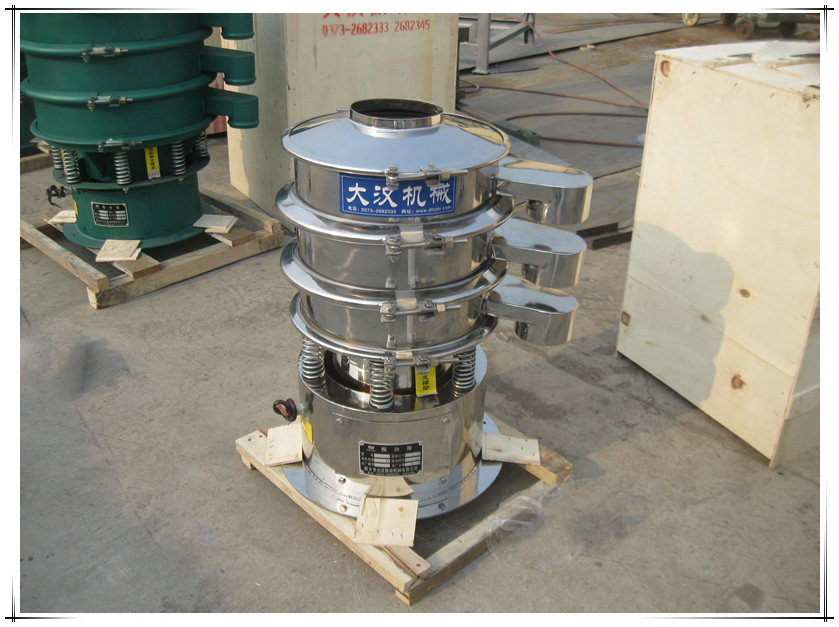

Stainless steel vibrating sieve machine is mounted with 0.18kw vertical vibrating motor.There are the diameter of 400mm,two layer screen mesh with three dischange holes.Mainly used in screening material with high output.Accept customized service.

Stainless steel vibrating sieve machine use upright motor as the source of vibration,equipped eccentricity hammer on the both sides of motor ,change circumrotate to level, upright and incline movement, then pass these three movement to the surface of the screen.Adjust the phasic angle on the both sides of the top and bottom to change the movement orbits of the surface screen.

►Features

►Features

1. High efficiency, refined design, duration,any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenience washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration of screen, only 3-5 to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 lagers are suggested.

►Applications

Chemical industry: resin,coating,drug industry,cosmetic,oil,Herbal powder,ect.

Chemical industry: resin,coating,drug industry,cosmetic,oil,Herbal powder,ect.

The food industry: sugar, gourmet powder, salt, fruit juice, starch, milk powder, food, soya-bean milk, egg powder, rice, soy, fish meal, pineapple juice, etc.

Metals, metallurgical mining: aluminite powder,lead powder,copper powder,ore,alloy powder,electrode powder,abrasive powder,refraclory materials,kaolin,lime,aluminium oxide,quartz sand,ect.

►Installation and adjustment

►Installation and adjustment

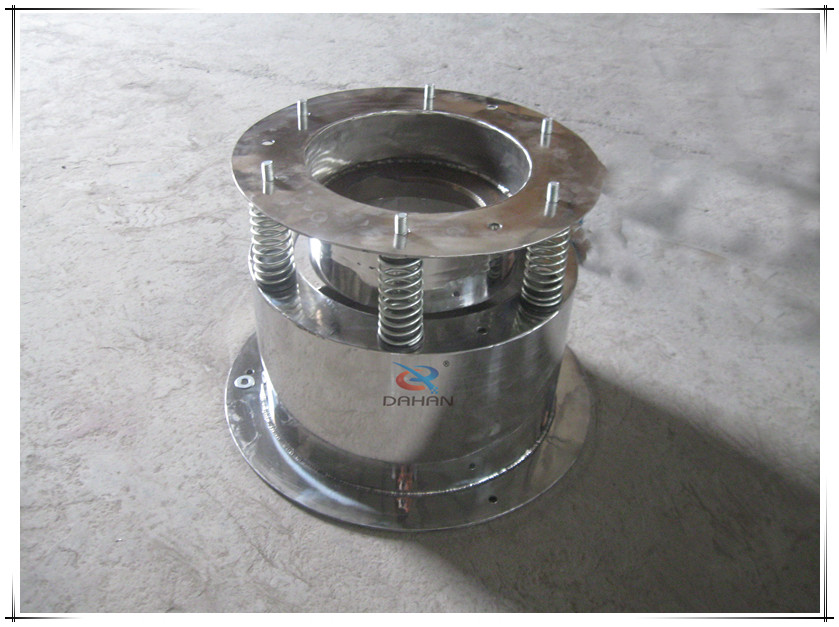

1, the motor should be fastened on the mounting surface, mounting surface must be smooth, flat.

2, the motor can be installed horizontally.

3, the electrical lead-core rubber cable with four-YZ-500V, then the power cable is not allowed when there is acute Lead off, and with the vibration of the body and firmly secured.

4, electrical grounding should be reliable, the motor grounding device, lead terminal signs, can also use foot bolts solid ground.

5, the exciting force adjustments.