Manual Mixing:

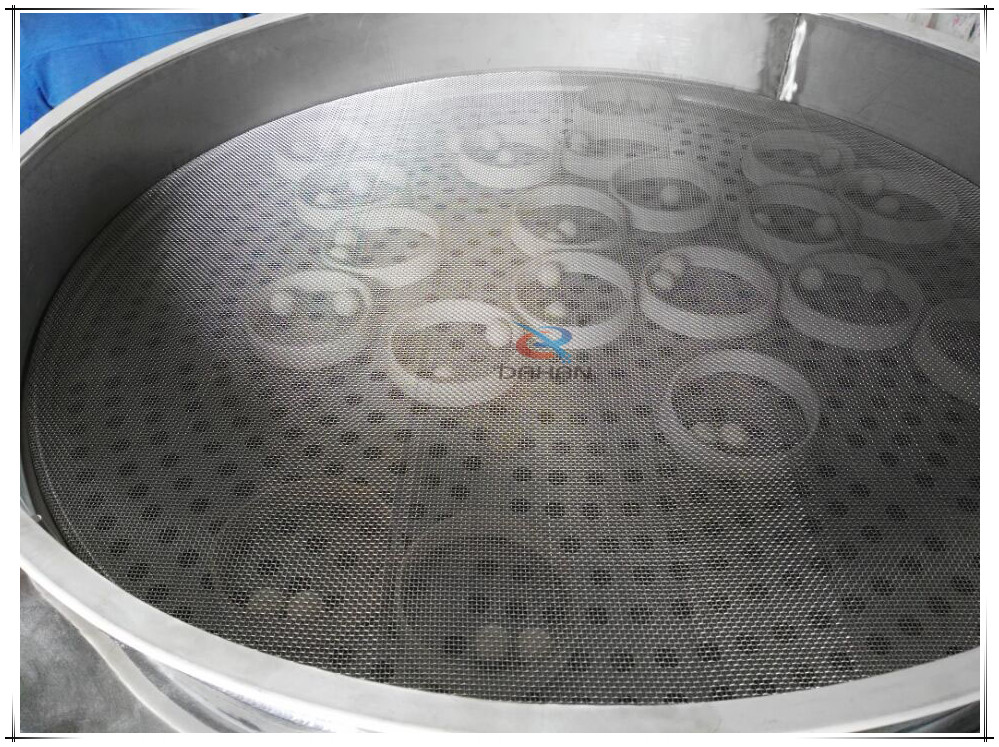

1200mm single layer Valve type vibrating sieve is mounted with 1.1kw vertical vibrating motor.There are the diameter of 1200mm,one layer screen mesh with two dischange holes.Mainly used in screening material with high output.Accept customized service.

Single layer Valve type vibrating sieve is a kind of high precision fine powder screening machine.Single layer Valve type vibrating sieve use upright motor as the source of vibration,equipped eccentricity hammer on the both sides of motor,change circumrotate to level, upright and incline movement, then pass these three movement to the surface of the screen.Adjust the phasic angle on the both sides of the top and bottom to change the movement orbits of the surface screen.

►Features

1. Widely used in any powder and liquid material;

2. Easy to change mesh, convenient to clean the mesh;

3. Dust-proof ;

4. Mesh size could be 2~1000 mesh or 0.013mm~8mm;

5. Little volume, easy to install according to requirement;

6. Max. 5 layers, 3 layers is better;

7. Carbon steel , stainless steel material or customized material;

8. Little power consumption, energy conservation and environmental protection, and can be installed indoor or outdoor;

►Application and using site of customer

Chemical industry: resin,coating,drug industry,cosmetic,oil,Herbal powder,ect.

The food industry: sugar, gourmet powder, salt, fruit juice, starch, milk powder, food, soya-bean milk, egg powder, rice, soy, fish meal, pineapple juice, etc.

Metals, metallurgical mining: aluminite powder,lead powder,copper powder,ore,alloy powder,electrode powder,abrasive powder,refraclory materials,kaolin,lime,aluminium oxide,quartz sand,ect.

►Use and maintenance

►Use and maintenance

1, the machine shall be equipped with electrical protection device.

2, the machine is running early, check every day at least once a bolt to prevent loosening.

3, when the motor direction of rotation does not meet the requirements, you can adjust the power supply phase sequence.

4, the motor should guarantee good lubrication, each running about two weeks to add lithium grease (ZL-3) once, come on, through the oil by adding appropriate amount of lithium grease cup.

5, the machine running total of 1500 hours, check the bearings, if serious injury should be immediately replaced.

6, the machine parked or garaged when used again after a long time, measure the insulatio n resistance should be used to measure 500-volt megger.