Manual Mixing:

Circle vibrating screen meet pharmaceutical standards requipmentequiped with special explosion-proof 0.25kw vibrating motor.Its diameter is 600mmwith two discharge hole and one screen meshmade of 304 stainless steelinside and outside polishing operation.

Circle Vibrating screen is designed as a high-precision screening machinery. Diameter can be ranged from 400mm to 2000mm, with single or multiple screening decks(1-5 layers).Material can be divided into all carton steel,contact part stainless steel, all stainless steel and anothers.Vibrating screen use vertical Explosion-proof vibrating motor or special vibration exciter as its vibration source.The vibrating motor or special vibration exciter has an eccentric block at both their upper and lower sides.The eccentric blocks can generate a three-diamensional movement in horizontal,vertical and inclined directions.By adjusting the phase angles of the upper and lower eccentric blocks,the material on the screen mesh can change the movement locus,achieving suitable screening performance.

►Structure chart

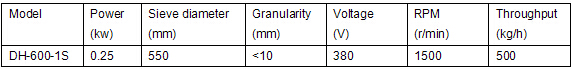

►Technical Parameters

►Features

a.Layers can be up to five layers;

b.Fully enclosed design,continuous operation,small volume,easy to move and low noise;

c.Self-cleaning device,avoiding block screen mesh, mesh size can reach to 500 mesh ( 0.028 mm);

d.High precision, high efficiency, kinds of powder, granule and mucus are applicable.

►Application

Chemical industry: resin,coating,drug industry,cosmetic,oil,Herbal powder,ect.

The food industry: sugar, gourmet powder, salt, fruit juice, starch, milk powder, food, soya-bean milk, egg powder, rice, soy, fish meal, pineapple juice, etc.

Metals,metallurgical mining: aluminite powder,lead powder,copper powder,ore,alloy powder,electrode powder,abrasive powder,refraclory materials,kaolin,lime,aluminium oxide,quartz sand,ect.

Pls provide the following information for us:

1. material name, the density(kg/m3), water content(%).

2. the necessary capacity you required(per hour)

3. Machine material. Pls choose one:

a. All stainless steel 304

b. All carbon steel

c. The contacting part is stainless steel,the other parts is carbon steel or spraying plastic.

d.Contact part with plastic.

4. the dimension of the machine can be designed for you.

5. How many layers you need?