Manual Mixing:

With the diameter of 800mm,two screen meshes,three discharge holes

High-precision sieving

Not block the screen

Easy to move

Easy to change screen mesh

Vibratory screen is designed as a high-precision screening machinery. Diameter can be ranged from 400mm to 2000mm, with single or multiple screening decks(1-5 layers).Material can be divided into all carton steel,contact part stainless steel, all stainless steel and anothers.Vibratory screen use vertical Explosion-proof vibrating motor or special vibration exciter as its vibration source.The vibrating motor or special vibration exciter has an eccentric block at both their upper and lower sides.The eccentric blocks can generate a three-diamensional movement in horizontal,vertical and inclined directions.By adjusting the phase angles of the upper and lower eccentric blocks,the material on the screen mesh can change the movement locus,achieving suitable screening performance.

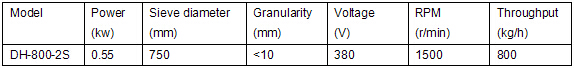

►Technical Parameters

►Advantage

♦ High efficiency,design is exquisite and durable, any powder mucoid screening.

♦ Easy to change screen, easy to operate and easy to clean.

♦ Mesh is not blocked,Powder is not float in the sky,Mesh to 500 mesh or 0.028 mm.

♦ Impurity,coarse material automatic discharge;Can connect operation.

♦ Unique network frame design, screen mesh use time long, fast to replace the network only for 3 to 5 minutes.

♦ Small volume, saving space, easy to move.

♦ Screen up to five layers.