Manual Mixing:

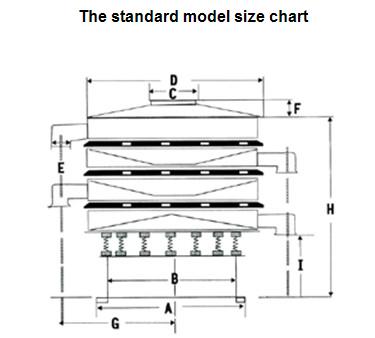

DH-1800-3S rotary vibrating sieve is mounted with 2.2kw vertical vibrating motor.There are the diameter of 1800mmthree la

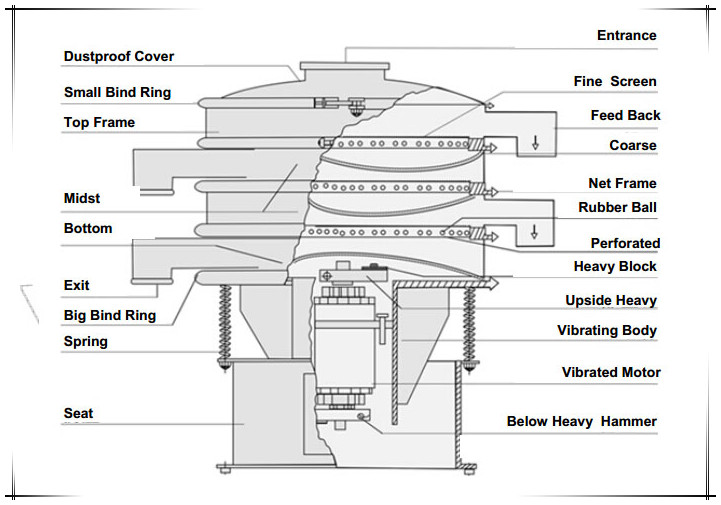

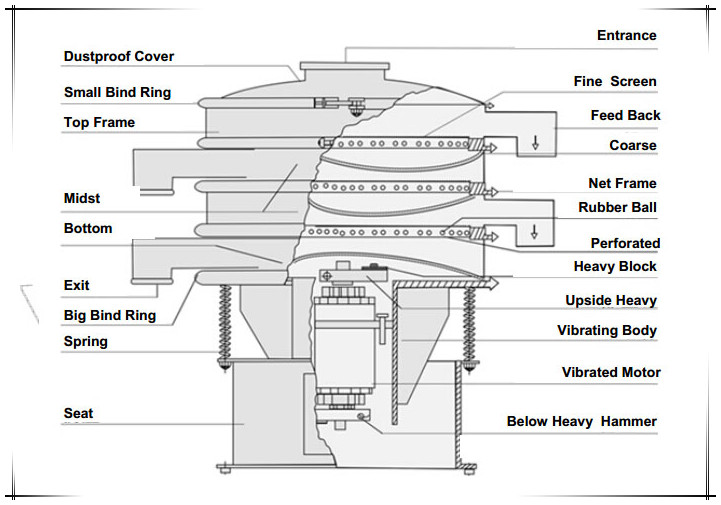

Rotary vibrating screen is a kind of high precision fine powder screening machine, works by the upright motor as vibration source, installed on both ends of the motor on the eccentric hammer, the motor rotation movement into horizontal vertical slope of three dimensional movement, then pass the movement to the screen surface at the ends of the regulation on the phase Angle, can change the course of movement on the surface of the material in the screen, vibration due to its operation principle, many enterprises are also called the three dimensional vibrating screen filter, according to shape structure is part of the customers' call for circular screen, from the material point of standard sieve and normal vibration sieve, and material contact part of the standard of 304 stainless steel material, base for carbon steel material, the ordinary type of the brick for carbon steel material.

►Rotary vibrating screen`s feature

♦ High efficiency,design is exquisite and durable, any powder mucoid screening.

♦ Easy to change screen, to operate and to clean.

♦ Mesh is not blocked,Powder is not float in the sky,Mesh to 500 mesh or 0.028 mm.

♦ Impurity, coarse material automatic discharge;Can connect operation.

♦ Unique network frame design, screen mesh use time long, fast to replace the network only for 3 to 5 minutes.

♦ Small volume, saving space, easy to move.

♦ Screen up to five layers.

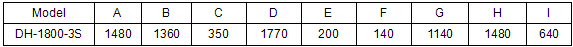

►The overall size of rotary vibrating screen

►Machine maintenance

►The overall size of rotary vibrating screen

►Machine maintenance

Routine maintenance

1.start ago:(1)check the coarse and fine mesh with or without breakage

(2)Whether locking in each beam ring

2.during start:(1)note: whether there is abnormal noise

(2)whether the current stability

(3)whether abnormal vibration

3.after use:clean after each use.

Regular maintenance

Regular inspection coarse mesh, fine mesh and springs whether fatigue and breakage,whether all parts of the machinecause damage due to vibration, need to add lubricant section must be ubricated.