Manual Mixing:

Hopper Automatic sieving machine is mounted with 0.25kw vertical vibrating motor.There are the diameter of 600mm,one layer screen mesh with two dischange holes.Mainly used in screening material of high output,made of stainless steel.Accept customized service.

Hopper Automatic sieving machine is designed as a high-precision screening machinery.DH series circle vibrating sieve is a vertical-motor system, with eccentric hammers being installed on top and bottom of the machine,where the vibration motor acts as the vibratory source.The direction of the eccentric hammers may change its rotational mode either in horizontal,vertical and inclined movement onto the sieving screener surface.

►Features

1. Widely used in any powder and liquid material;

2. Easy to change mesh, convenient to clean the mesh;

3. Dust-proof ;

4. Mesh size could be 2~1000 mesh or 0.013mm~8mm;

5. Little volume, easy to install according to requirement;

6. Max. 5 layers, 3 layers is better;

7. Carbon steel , stainless steel material or customized material;

8. Little power consumption, energy conservation and environmental protection, and can be installed indoor or outdoor;

►the replace of screen mesh

(1)First loose screw of beam ring,remove the frame,the fine mesh broken removed and replaced with a new fine mesh.

(2)The fine mesh tile in the mother mesh,again put the upper ledge back in place,fine mesh stretched by hand from the surrounding.At both ends of the machine on the side edge of the box,each using a universal clamp,the clamp on the upper frame and the next frame.

(3)The fine mesh around the protruding edge of the frame except reserved two centimeters,the rest all cut.

(4)Beam ring Again put,loose universal clamp.Then tighten the screw of beam ring.

(5) Evenly beat around the beam ring with a soft hammer,locknut,that completed the replacement of a fine mesh.

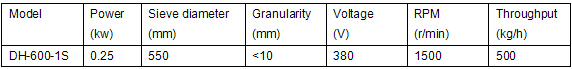

►Parameters

►Installation and adjustment

1, the motor should be fastened on the mounting surface, mounting surface must be smooth, flat.

2, the motor can be installed horizontally.

3, the electrical lead-core rubber cable with four-YZ-500V, then the power cable is not allowed when there is acute Lead off, and with the vibration of the body and firmly secured.

4, electrical grounding should be reliable, the motor grounding device, lead terminal signs, can also use foot bolts solid ground.

5, the exciting force adjustments.