Manual Mixing:

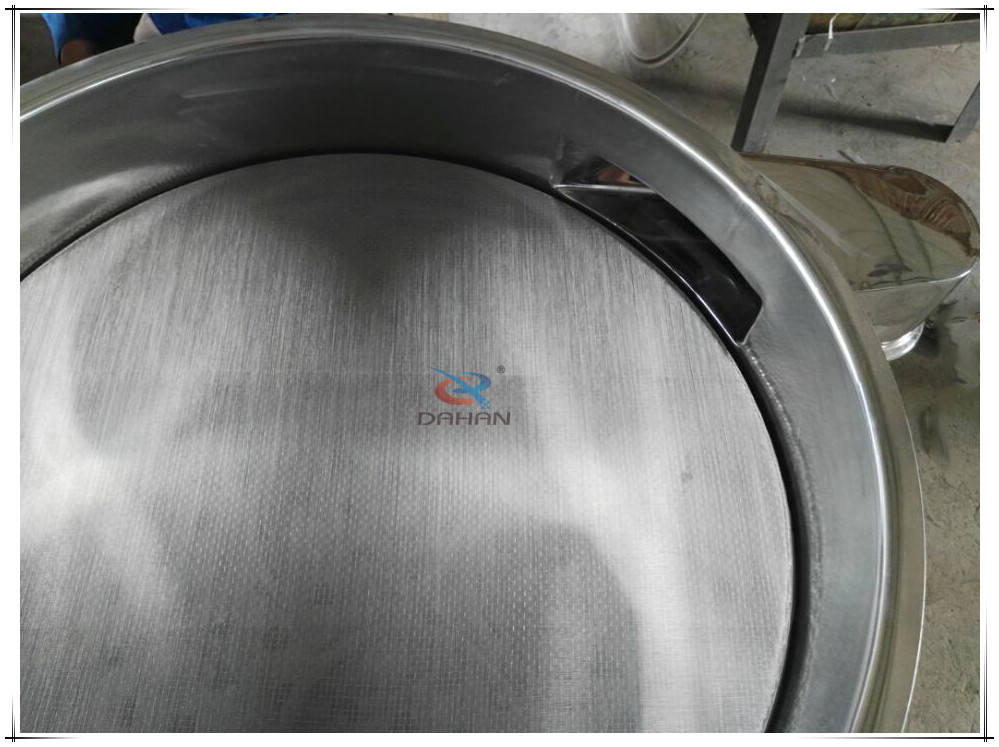

Hopper type movable vibrating sieve is mounted with 0.25kw vertical vibrating motor.There are the diameter of 600mm,one layer screen mesh with two dischange holes.Mainly used in screening material with high output.Accept customized service.

Hopper type movable vibrating sieve is designed as a high-precision screening machinery.DH series circle vibrating sieve is a vertical-motor system, with eccentric hammers being installed on top and bottom of the machine,where the vibration motor acts as the vibratory source.The direction of the eccentric hammers may change its rotational mode either in horizontal,vertical and inclined movement onto the sieving screener surface.

►Features

♦ High efficiency,design is exquisite and durable, any powder mucoid screening.

♦ Easy to change screen, easy to operate and easy to clean.

♦ Mesh is not blocked,Powder is not float in the sky,Mesh to 500 mesh or 0.028 mm.

♦ Impurity,coarse material automatic discharge;Can connect operation.

♦ Unique network frame design, screen mesh use time long, fast to replace the network only for 3 to 5 minutes.

♦ Small volume, saving space, easy to move.

♦ Screen up to five layers.

►Pls provide the following information for us:

1. material name, the density(kg/m3), water content(%).

2. the necessary capacity you required(per hour)

3. Machine material. Pls choose one:

a. All stainless steel 304

b. All carbon steel

c. The contacting part is stainless steel,the other parts is carbon steel or spraying plastic.

d.Contact part with plastic.

4. the dimension of the machine can be designed for you.

5. Additional parts ,like the mobil wheel, removing-dust hole and noise-proof base,can be easily fixed and maintained.

6. How many layers you need??

7. Pls inform the voltage&frequency in your city.

►Application

►Use and maintenance

►Application

Chemical industry: resin,coating,drug industry,cosmetic,oil,Herbal powder,ect.

The food industry: sugar, gourmet powder, salt, fruit juice, starch, milk powder, food, soya-bean milk, egg powder, rice, soy, fish meal, pineapple juice, etc.

Metals, metallurgical mining: aluminite powder,lead powder,copper powder,ore,alloy powder,electrode powder,abrasive powder,refraclory materials,kaolin,lime,aluminium oxide,quartz sand,ect.

►Use and maintenance

1, the machine shall be equipped with electrical protection device.

2, the machine is running early, check every day at least once a bolt to prevent loosening.

3, when the motor direction of rotation does not meet the requirements, you can adjust the power supply phase sequence.

4, the motor should guarantee good lubrication, each running about two weeks to add lithium grease (ZL-3) once, come on, through the oil by adding appropriate amount of lithium grease cup.

5, the machine running total of 1500 hours, check the bearings, if serious injury should be immediately replaced.

6, the machine parked or garaged when used again after a long time, measure the insulatio n resistance should be used to measure 500-volt megger.