Manual Mixing:

2-deck starch vibrating sieve is mounted with 0.18kw vertical vibrating motor.There are the diameter of 400mm,two layers screen mesh with three dischange holes.Mainly used in screening material with high output.Accept customized service.

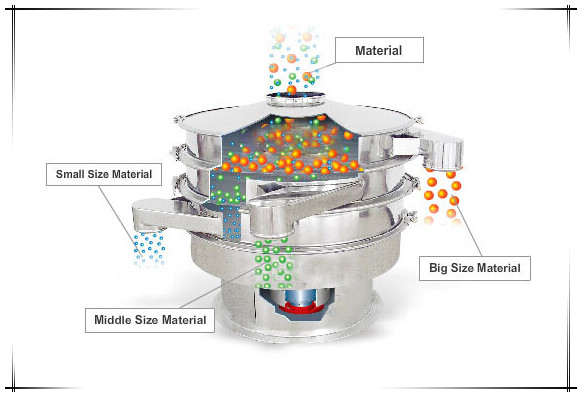

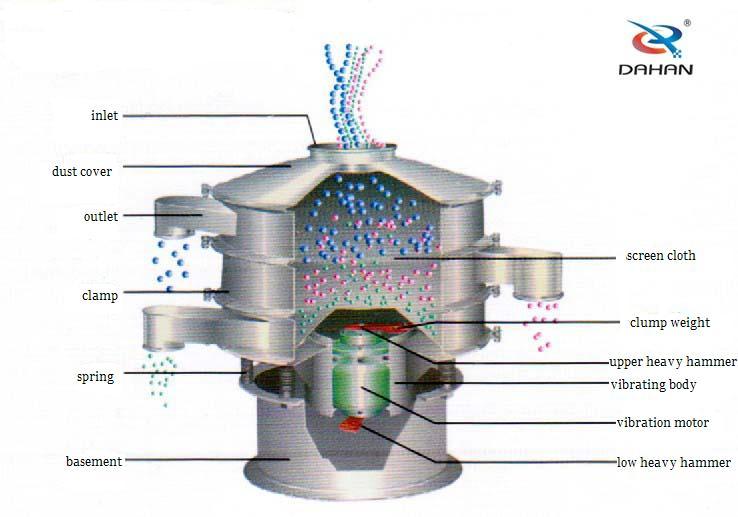

2-deck starch vibrating sieve is designed as a high-precision screening machinery. Electric vibrating sieve is composed of vertical motor,and eccentric weight installed at two ends.We can produce horizontal, vertical, inclined motions by adjusting the upper and lower eccentric weight.Diameter can be ranged from 400mm to 2000mm, with single or multiple screening decks(1-5 layers).Material can be divided into all carton steel,contact part stainless steel and all stainless steel.

►Features

♦ High efficiency,design is exquisite and durable, any powder mucoid screening.

♦ Easy to change screen, easy to operate and easy to clean.

♦ Mesh is not blocked,Powder is not float in the sky,Mesh to 500 mesh or 0.028 mm.

♦ Impurity,coarse material automatic discharge;Can connect operation.

♦ Unique network frame design, screen mesh use time long, fast to replace the network only for 3 to 5 minutes.

♦ Small volume, saving space, easy to move.

♦ Screen up to five layers.

►Manufacturing details

►Application industry

The 2-deck starch vibrating sieve can be used in ceramic powder, resin, coating, silica gel, sugar powder, rice, flour, condiment, aluminite powder, mineral powder, abrasion powder, silicon carbide, silica sand metallurgy, medicine, metal, food, fine material etc.

►Manufacturing details

►Application industry

The 2-deck starch vibrating sieve can be used in ceramic powder, resin, coating, silica gel, sugar powder, rice, flour, condiment, aluminite powder, mineral powder, abrasion powder, silicon carbide, silica sand metallurgy, medicine, metal, food, fine material etc.

►Use and maintenance

1, the machine shall be equipped with electrical protection device.

2, the machine is running early, check every day at least once a bolt to prevent loosening.

3, when the motor direction of rotation does not meet the requirements, you can adjust the power supply phase sequence.

4, the motor should guarantee good lubrication, each running about two weeks to add lithium grease (ZL-3) once, come on, through the oil by adding appropriate amount of lithium grease cup.

5, the machine running total of 1500 hours, check the bearings, if serious injury should be immediately replaced.

6, the machine parked or garaged when used again after a long time, measure the insulatio n resistance should be used to measure 500-volt megger.